When we prepare samples for analysis by XRF we tend to use a simple pressed powder preparation method in the first instance. The depth of the sample is important for calculating matrix density and in correcting for non-infinite depth samples (thin samples and/or those with a low average atomic number). We used to use a standard digital caliper, but it wasn’t ideal. The 150 mm calipers we had were unwieldy, and it care was needed to accurately level the depth gauge probe.

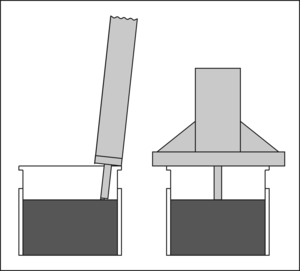

Enter the digital tyre depth gauge! These digital tyre depth gauges are easy to find online for a few quid. They have a nice wide guide, and as you can see with a range of up to 25 mm, they are perfect for measuring the depth in XRF loose-powder pots (we use pots that are nominally 22 mm tall). The method goes:

- Zero the display whilst measuring the depth of the empty pot.

Measure from the top of the pot to the base, and zero the display. - Fill the pot with sample, press and weigh.

- Measure to the top of the sample from the top of the pot.

Having filled the pot with the sample, probe from the top of the pot to the sample surface. - The height of the sample is the additive inverse of the reading (that is, -7.45 mm is 7.45 mm).